Silicone Gels for use in Electronics

Silicone Gels for use in Electronics

Silicone gels are two-component, addition (platinum) cure chemistry and most are designed with a one-to-one mix ratio system. Silicone gels will cure at either room temperature or can be heat cured for faster processing and can be either automatically or hand dispensed. Specialty gels can also be formulated to only cure with the use of heat in order to achieve a very long pot life.

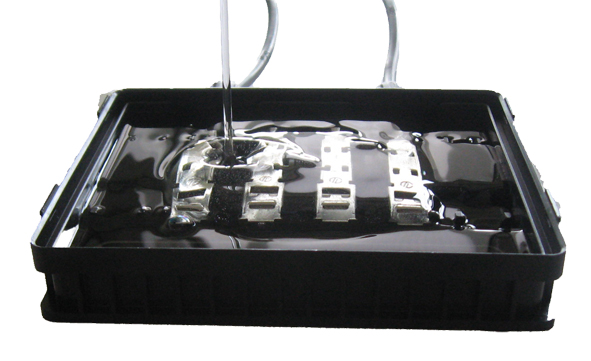

Silicone gels are used in numerous electronic applications when a soft and highly flexible encapsulation or potting is required. CHT’s silicone gels protect delicate components and assemblies from vibration, thermal and mechanical shock, as well as guard against moisture corrosion and other harsh environmental factors.

Many of CHT’s silicone gels are optically clear in appearance but can be tinted for visual identification. Also, if optical clarity is not required, fillers can be added to produce tougher, more rigid gels.

CHT’s silicone gels are available in a variety of hardnesses, penetrations and viscosities. Low viscosity gels will easily flow around complex components and thixo-gels can be applied where non-slumping or sagging is required. Silicone gels typically provide a primerless, “pressure sensitive” type bond to most substrates. However, chemical adhesion can be achieved through the use of a primer.

Properties include:

- Wide operating temperature range: -55ºC to 200ºC

- Excellent electrical properties

- Flame retardant, UL listed grades

- Range of refractive indices

- UV resistant non-yellowing catalysts

- Low modulus materials minimize CTE strain

- Good resistance to chemicals, water and humidity

- Repairable and self-healing grades

- Adhesion to many substrates including glass, aluminium, and copper

Industries: Electronics, Aerospace, Automotive, Solar/energy, Healthcare

Applications: Electronic protection, Optical bonding, Gap pads, Gap fillers

Several physical properties in CHT’s silicone gels are customisable including:

- Refractive index

- Adhesion

- Cure speed

- Color / Tint

- Penetration

- Viscosity

- Conductivity

Finding the right silicone for your application is not limited to CHT’s product portfolio. Our technical team will partner with you to either modify specifications in a current product or custom formulate a new one to meet your exact requirements.

For technical assistance or sample requests, please visit our contact page.

Product Listing

| Code | Description | Request Sample | TDS | SDS |

|---|---|---|---|---|

| ALPA-GEL M | Silicone Gel | |||

| CHT-BeauSil™ GEL 8014 | Silicone Crosspolymer for Personal Care | |||

| CHT-BeauSil™ GEL 8086 | Silicone Crosspolymer as an ingredient for Personal Care | |||

| EGel3000 | Silicone Gel | |||

| QGel 300 | High Strength Silicone Gel | |||

| QGel 300 Blue | 2 part Silicone Gel | |||

| QGel 300Y | High Strength, Yellow Tinted Silicone Gel | |||

| QGel 301 | Fast Curing, High Strength Silicone Gel | |||

| QGel 302 | Fast Curing, High Strength Silicone Gel | |||

| QGel 303 | Fast Curing, High Strength Silicone Gel | |||

| QGel 305 | High Strength Silicone Gel | |||

| QGel 307IR | Inhibition Resistant Silicone Gel | |||

| QGel 310 | General Purpose Silicone Gel | |||

| QGel 311 | General Purpose Silicone Gel | |||

| QGel 311UV | Special Purpose Silicone Gel with UV Tracer | |||

| QGel 312 | Custom Silicone Gel | |||

| QGel 313 | Custom Silicone Gel | |||

| QGel 314 | High Tack Silicone Gel | |||

| QGel 316 | General Purpose Silicone Gel | |||

| QGel 317 | General purpose silicone gel | |||

| QGel 319 | Optically clear silicone gel | |||

| QGel 322 | General purpose silicone gel | |||

| QGel 322Y | General purpose silicone gel | |||

| QGel 324 | General purpose silicone gel | |||

| QGel 326 | General purpose silicone gel | |||

| QGel 327 | General purpose silicone gel | |||

| QGel 329 | General purpose silicone gel | |||

| QGel 410 | General Purpose Silicone Gel | |||

| QGel 900 | High Refractive Phenyl Gel | |||

| QGel 910 | High refractive index Phenyl gel | |||

| QGel 920 | High refractive index Phenyl gel | |||

| TufGel 330 | Two-part, High Strength Silicone Gel | |||

| TufGel 331 | Two-part, High Strength Silicone Gel | |||

| TufGel 332 | Two-part, High Strength Silicone Gel | |||

| TufGel 333 | Two-part, High Strength Silicone Gel | |||

| TufGel 3350 | Two-part, Self-Bonding High Strength Silicone Gel | |||

| TufGel 336 | Two-part, Self-Bonding High Strength Silicone Gel | |||

| TufGel 338 | Two-part, High Strength Silicone Gel | |||

| TufGel 339 | Two-part, High Strength Silicone Gel |